Telescopic Sliding Gate Pulley System (Master and Trailing Sliding Gates) Maximum 4.5m/500KG EACH

SKU: TELESCOPIC500

$235.00

- Freight from $19.00 Calculate Freight

- 1 Year Warranty

- Brand : Alpha Automation

In stock

Click & Collect

Delivery

In-Store

In stock

Telescopic Sliding Gate Pulley System (Master and Trailing Sliding Gates) Maximum 4.5m/500KG EACH

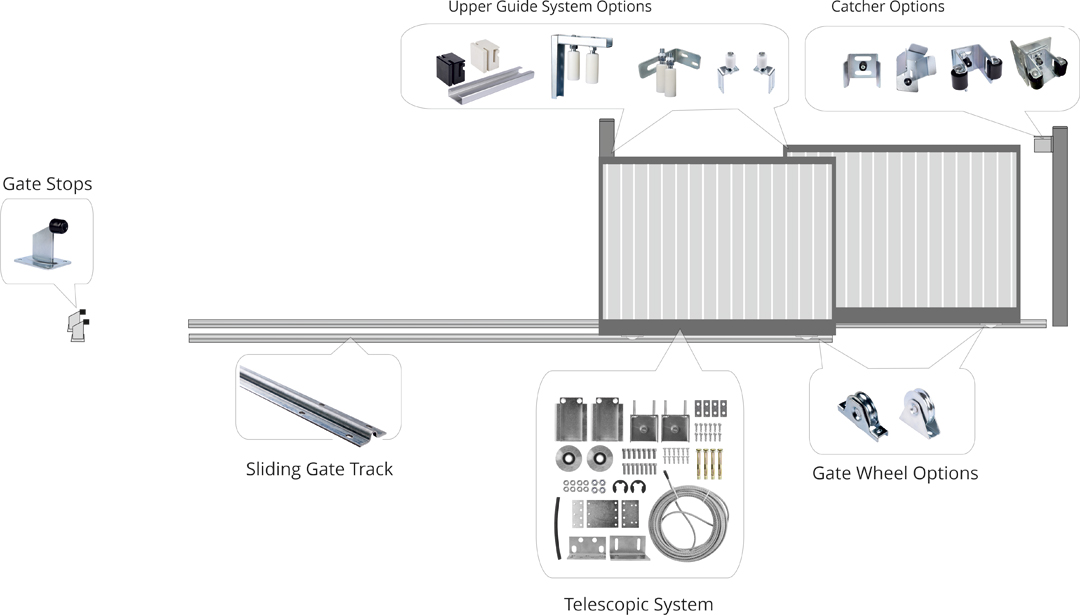

The heavy duty telescopic gate allows for a primary and trailing gate configuration to eliminate the amount of space requirement in which the sliding gate opens to. The kit will create an interconnection between the primary gate (back gate) and the secondary gate (front gate).

The primary gate (closest to inside the property) will incorporate both the adjustable pulley systems in which both operate on sealed bearings, the secondary gate will have its own exclusive bracket fitted directly to it (supplied) in which it will connect to the primary gates stainless steel pulley wire.

When the primary gate is moved the secondary will follow, when the secondary is moved the primary will follow (manual operations). If automated using a sliding gate motor, all movements are initiated by the connected primary gate

The telescopic gate system can work with all sliding gate wheels thanks to the supplied low and high base plate system thus supporting IRM wheels (Internal recess mount) and EFM wheel (external flat mount wheels and in terms of the guiding system it can work with roller and bracket arrangements as well as nylon block and angle arrangements.

The cleverly designed pulley system allows for up to 25mm (1 inch) of adjustment from either end of the primary gate to allow for a correctly tensioned system in turn allowing for smooth operation, The system is capable of 4500mm (4.5 Meters) per gate and a maximum of 250kg per gate, typically the tail section of the sliding gate is 350mm minimum thus allowing for an absolute maximum opening of 8300mm (8.3m).

Typical guidelines

✓ Primary gate width is half the opening +350mm minimum

✓Secondary gate width is also half the opening +350mm minimum

Ground Track

✓Primary gate requires floor track double its width

✓Secondary gate requires floor track double its width + half the driveway

✓A pair of wheels for each gate is required (total 4 wheels)

Support

✓A support post on the inside BEHIND the primary gate is required

✓A guiding system per gate is required (rollers and bracket OR nylon block and channel)

Facts about a telescopic sliding gate system

The secondary gate will move at twice the speed of the primary gate, essentially the load is at minimum doubled to tripled when automating, always use a higher specification DC motor such as the Titan 2410 (1000kg Capacity) DC sliding gate motor is strongly suggested for automation due to adjustable speed characteristics and slowdown smoothness and adjustment.